|

|||||

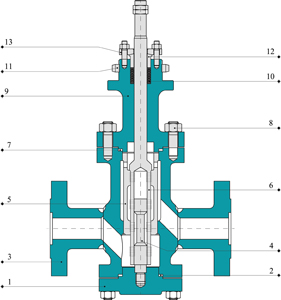

| 1 | 底座Base | A105 | 304 | 316 | 316L |

| 2 | 垫片Shim | 锯齿型金属垫片Saw tooth type metal gasket、金属石墨垫片Metal graphite gasket | |||

| 3 | 阀体Body | A105 | 304 | 316 | 316L |

| 4 | 导向杆Guide rod | 304 | 304 | 316 | 316L |

| 5 | 导向套Guide sleeve | 304 | 304 | 316 | 316L |

| 6 | 阀芯Seat | 304 | 304 | 316 | 316L |

| 7 | 垫片Shim | 锯齿型金属垫片Saw tooth type metal gasket、金属石墨垫片Metal graphite gasket | |||

| 8 | 螺丝螺母Screw nu | 304 | 304 | 316 | 316L |

| 9 | 阀盖Valve cover | A105 | 304 | 316 | 316L |

| 10 | 填料Packing | 聚四氟乙烯PTFE、柔性石墨Flexible graphite | |||

| 11 | 锁紧螺母Lock nut | 304 | 304 | 316 | 316L |

| 12 | 压套Pressing ring | 304 | 304 | 316 | 316L |

| 13 | 压板Plate | 304 | 304 | 316 | 316L |

| Model Form |

Pneumatic actuator | Electronic electric actuator |

| ZH23~ZH56 | 3810L RSL | |

| Multi spring type | Intelligent integration | |

| Use | Regulating、Switch | Regulating |

| Drive | pressure(range of spring) 140(20~100)Kpa G 240(40~200)Kpa G 280(80~240)Kpa G |

Power Supply: AC 220 V ±10% 50Hz Power Supply: AC 380 V ±10% 50Hz |

| Joint | Rc 1/4 | Popular type: 2-PF (G1/2") Explosion proof type: 2-PF (G3/4") |

| Positive effect | Air pressure increase to drive the valve close | Control signal increase to drive the valve close |

| Reaction | Air pressure increase to drive the valve open | Control signal increase to drive the valve open |

| Control signal | 4~20mA.DC(Tape locator) | Input output 4~20mA.DC |

| Hysteresis | ≤ 1% FS (Tape locator) | ≤ 0.8% FS |

| Linearity | 2% FS (Tape locator) | ≤ ±1% FS |

| Temperature | -10~+70℃ | |

| Surface coating | Body:Black phosphating treatment Actuator:acrylic polyurethane enamel |

|

| Optional accessories | Valve positioner Handwheel Solenoid valve Travel switch Position valve |

Heater |

| Flow characteristics | Equal percentage、Straight line | ||

| Adjustable range | 50:1 | ||

| Rated Cv value | The percentage etc:5~300 | ||

| Allowable leakage | Metallic seal:III (0.5% valve rated flow);soft seal: v | ||

| Performance index | Driving mode | Pneumatic | Electric |

| Intrinsic error % | ± 1.0 | ± 1.0 | |

| Return difference % | ≤ 1.0 | ≤ 1.0 | |

| Dead zone % | ≤ 0.6 | ≤ 1.0 | |

| Switch deviation % | ± 2.5 | ± 2.5 | |

| Deviation of stroke % | ≤ 2.5 | ≤ 2.5 | |